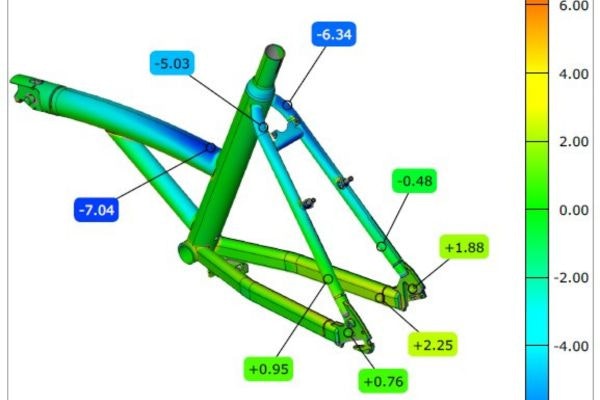

The GOM brand ATOS Scanbox uses lasers to provide a full-field 3D coordinates for each measurement. Within a few seconds, up to 16 million independent measuring points are captured per scan. The turntable in the scan box automates the entire process. Thus, the object does not have to be turned manually in all directions.

The scanner projects a grid while the camera measures the formation of the object. The angle between the camera and the laser, the distance between the camera, the laser and the object are used to determine the spatial coordinates of the object. Reference points on the rotating plate allow the scanner to determine the dimensions of the object and to easily fit multiple scans together to create one 3D-model. A positive advantage is that it has a high accuracy level of 0.02 mm. As a result, the measuring data is characterized by very high detailed reproduction, thereby enabling very small component features to be measured.